Calcium Silicate Boards for Fire & Thermal Insulation - Available in 6 mm to 100 mm

Explore premium calcium silicate boards for fire-rated ceilings, partitions, and insulation. Class A fireproof, moisture-resistant, high-temperature boards available across India.

Welcome to Wedge India, your trusted source for high-performance Calcium Silicate Boards. Engineered for exceptional durability and versatility, our boards are the ultimate solution for a wide range of demanding applications, from advanced thermal insulation and passive fire protection to robust construction for ceilings and partitions.

Experience the perfect blend of strength, safety, and sustainability with our non-asbestos, eco-friendly boards. Whether you're an architect, builder, or industrial contractor, explore how Wedge India's Calcium Silicate Boards deliver unmatched reliability and long-term value for your projects.

Price of Calcium Silicate Boards & Selection Guide

Find the perfect insulation or fire protection solution for your project in minutes. Our Wedge India Product Selection Guide gives you instant access to a complete overview of all our calcium silicate boards and blocks, organized by application, density, temperature rating, and fire rating. Top 30 Potential SKUs – Wedge India Calcium Silicate:

A. Light Density CaSi Boards (W-LD Series)

-

W-LD650 – 25 mm (Steel, glass, cement back-up insulation, 650 °C)

-

W-LD650 – 50 mm (Preferred for kiln linings, 650 °C)

-

W-LD900 – 25 mm (Chemical plants, 900 °C)

-

W-LD900 – 50 mm (Furnace/cyclone separators, 900 °C)

-

W-LD1100 – 25 mm (General industrial insulation, 1100 °C)

-

W-LD1100 – 50 mm (High-temp process plants, 1100 °C)

B. High Density CaSi Boards (HD Series)

-

HD150 – 25 mm (High compressive strength, pipe supports, 900 °C)

-

HD150 – 50 mm (Die-casting base insulation, 900 °C)

-

HD280 – 25 mm (Precision machining, 1000 °C)

-

HD280 – 50 mm (Machine cladding/heat shields, 1000 °C)

-

HDT1000 – 25 mm (High-strength load bearing, 1000 °C)

-

HDT1000 – 50 mm (Tank/furnace supports, 1000 °C)

C. Molten Aluminium Contact Boards

-

HD900 – 25 mm (Non-wettable ladles, launders, 1000 °C)

-

HD900 – 50 mm (Aluminium holding furnaces)

-

Z140 – 25 mm (Casting floats, spouts, hot top rings)

-

Z140 – 50 mm (Molten Al launders, baths)

-

M1000 – 25 mm (Molten Al furnace applications)

-

M1000 – 50 mm (Continuous casting, molten Al contact)

D. Graphite Reinforced CaSi Boards (W-CMA Series)

-

W-CMA – 25 mm (High load, non-wetting Al, bushings)

-

W-CMA – 50 mm (Transport launders, spouts)

-

W-C18 – 25 mm (Transition plates, tips)

-

W-C18 – 50 mm (Hot top rings, filter boxes)

E. Wollastonite & Fire Boards

-

HSI1200 – 25 mm (Wollastonite backup insulation, 1200 °C)

-

HSI1100 – 25 mm (Wollastonite board, backup insulation, 1100 °C)

-

FP1000 – 25 mm (Fire board, structural steel protection, FD240 min rating)

F. Special & Sandwich Panels

-

HDSP450 – 25 mm (Asbestos-free sandwich panel, 450 °C)

-

RIMB 1100 – 25 mm (High-temp millboard, gasketing, 1100 °C)

-

C45 – 25 mm (Molten aluminium furnace & casting)

-

WL101 – 25 mm (Graphite reinforced – filter boxes, headers)

-

L23 – 25 mm (High density load bearing, arc chutes, 350 °C–900 °C)

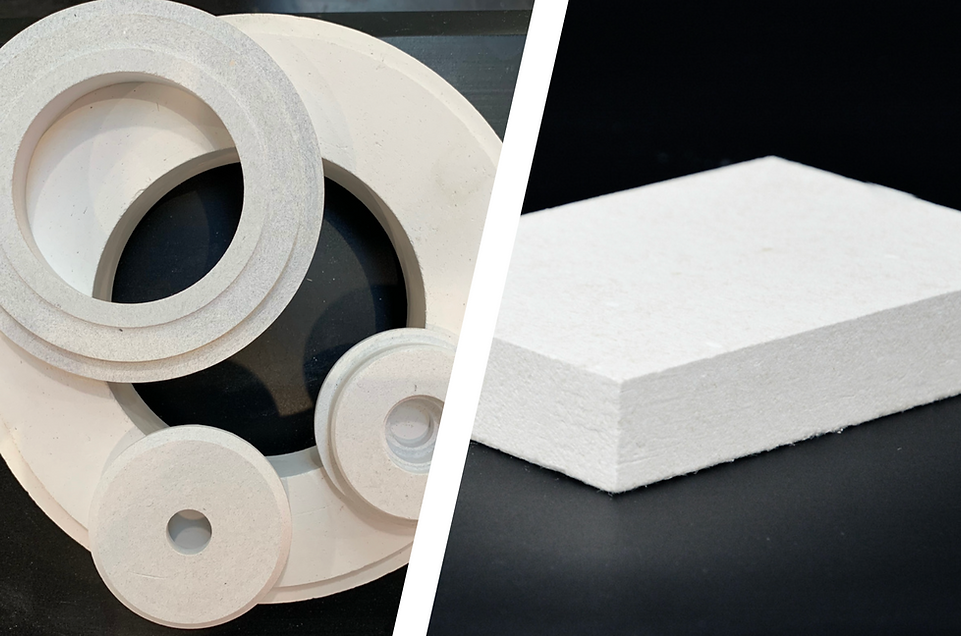

What is Calcium Silicate Board?

Calcium silicate board is a high-performance, versatile building material renowned for its exceptional fire resistance, thermal insulation, and long-lasting durability. Engineered from a blend of calcium, silicon, and natural reinforcing fibers, it is completely free from asbestos, making it an eco-friendly and safe choice for modern construction.

Ideal for use in false ceilings, drywall partitions, wall cladding, and specialized industrial applications, calcium silicate board delivers outstanding protection against heat, flames, moisture, and termites. Its smooth, paint-ready surface and excellent dimensional stability ensure easy installation and a flawless finish—whether you’re designing residential interiors, commercial spaces, or demanding industrial environments.

With industry-leading certifications for quality and environmental safety, calcium silicate boards are trusted by architects, builders, and engineers across India for projects where superior fireproofing, insulation, and structural integrity are non-negotiable. Choose calcium silicate board to ensure safety, efficiency, and long-term value for your next project.

Features & Benefits Calcium Silicate

-

High Thermal Insulation: Excellent at reducing heat transfer, making them ideal for high-temperature environments.

-

Fire Resistance: Non-combustible, providing a high degree of safety in industrial settings.

-

Durability: Resistant to physical wear and tear, moisture, and chemical attack.

-

Low Thermal Conductivity: Maintains consistent insulating properties across a wide range of temperatures.

-

Dimensional Stability: Maintains shape and effectiveness even under high temperatures and varying conditions.

-

Lightweight: Easier to handle and install compared to other high-density insulation materials.

Benefits in Industrial Applications

-

Energy Efficiency: Helps in maintaining consistent temperatures and reducing energy consumption in industrial processes.

-

Safety: Enhances fire protection, reducing the risk of fire hazards in industrial plants.

-

Cost-Effective: Long lifespan and low maintenance requirements lead to cost savings over time.

-

Environmental Resistance: Effective in harsh environments where moisture, chemicals, and high temperatures are prevalent.

-

Ease of Installation: Can be cut and shaped on-site to fit various industrial equipment and structures.

Calcium Silicate Board Product Range - Wedge India

1. Low-Density Calcium Silicate (W-LD Series)

-

Grades: W-LD 650, 900, 1000, 1100

-

Density: 220–255 kg/m³

-

Service Temp: 650–1100°C

-

Applications: Steel & cement plant furnaces, kiln linings, glass melting channels, petrochemical reactors.

-

Advantages: Lightweight, low thermal conductivity (0.062–0.105 W/m·K), moisture and chemical resistance.

2. High-Density Calcium Silicate (HD Series)

-

Grades: HD900, HD1000, HD280, HDL23, T1000, HD850

-

Density: 750–1800 kg/m³

-

Service Temp: 900–1000°C

-

Applications: Pipe supports, furnace shields, load-bearing insulation, die-casting components.

-

Advantages: High compressive strength (up to 85 MPa), excellent machinability.

3. Fire-Resistant Calcium Silicate Boards (FP & SP Series)

-

Grades: FP1000, SP1150

-

Fire Rating: Up to 240 minutes at 10 mm thickness

-

Applications: Structural steel protection, fire-rated partitions & ceilings, fire doors, tunnel lining.

-

Advantages: High acoustic & thermal insulation, unaffected by humidity, A1 non-combustible.

4. Specialized Non-Wetting & Graphite-Reinforced Grades

-

Grades: CMA, C18, CCG4, WL100, Z140, M1000, C45

-

Applications: Molten aluminum handling (launders, troughs, floats, spouts), EV battery fire barriers.

-

Advantages: Non-wettable, low shrinkage, easy to clean.

5. High-Temperature Wollastonite-Calcium Silicate (HSI & RIMB Series)

-

Service Temp: 1000–1260°C

-

Applications: Furnace backup insulation, high-temp gasketing, fire doors, stainless steel plant rollers.

-

Advantages: Very strong boards, low thermal conductivity at high temps, high electrical resistance.

Why Choose Wedge India?

-

Complete portfolio for both industrial and building fire protection needs.

-

High performance – Temperature resistance up to 1400°C, fire ratings up to 240 minutes.

-

Local manufacturing advantage – Shorter lead times, lower logistics cost.

-

Value-added fabrication – CNC machining for ready-to-install shapes.

-

Certified solutions – Targeting NBC-compliant and BIS-approved fire protection systems.

FAQs - Wedge India Calcium Silicate Products

Q1: What is calcium silicate board used for?

A: It is a high-performance insulation and fire protection material used in buildings, industrial furnaces, and equipment operating at high temperatures.

Q2: Are Wedge India calcium silicate boards asbestos-free?

A: Yes, all our boards are 100% asbestos-free and safe for handling and installation.

Q3: What is the maximum temperature your boards can withstand?

A: Depending on the grade, our boards can handle continuous service temperatures from 650°C to 1100°C, and short-term exposure up to 1400°C.

Q4: Which industries use Wedge India calcium silicate boards?

A: Steel, cement, glass, petrochemicals, aluminum smelting, construction, data centers, and EV battery manufacturing.

Q5: How do your fire-resistant boards compare to Promat and Ramco Hilux?

A: Wedge India offers boards with comparable fire ratings (up to 240 minutes), certified non-combustibility, and superior value through local production and faster supply.

Q6: Can you supply pre-machined parts?

A: Yes, we offer CNC machining for custom parts like spouts, troughs, and complex insulation components.

Q7: Do you have certification for NBC compliance?

A: Yes, our end users OEM fire door manufacturers and system integrators have successfuly passed the fire tests at IPRITI and CBRI and secured CBRI Roorkee and BIS certifications for our fire protection systems.