Where Can I Find Insulation Materials for Cold Chain Logistics in Gurugram?

- Raj Arya

- Aug 11

- 4 min read

Introduction

In the world of cold chain logistics, maintaining precise temperatures is non-negotiable. Whether you are transporting pharmaceuticals, fresh produce, dairy, meat, or frozen foods, the right insulation materials are the backbone of your operation.

If you’re based in Gurugram — a major logistics hub for North India — Finding high-performance insulation materials is key to reducing energy loss, preventing spoilage, and ensuring product safety. Get all types of high performance Insulation Materials for Cold Chain Logistics at Wedge India.

Why Insulation is Critical for Cold Chain Logistics

Temperature Control – Prevents fluctuations that can compromise product quality.

Energy Efficiency – Reduces the load on cooling systems, saving operational costs.

Compliance – Helps meet FSSAI, WHO-GMP, and GDP standards for cold chain operations.

Longer Shelf Life – Maintains product integrity during storage and transit.

All Insulation Materials for Cold Chain Logistics at Wedge India

1. Rigid Panel Insulations

These are widely used for cold rooms, walk-in freezers, reefer trucks, and portable containers.

PIR (Polyisocyanurate) Panels – High thermal resistance, moisture-resistant, fire-rated.

PUF (Polyurethane Foam) Panels – Cost-effective, widely used for cold rooms and transport.

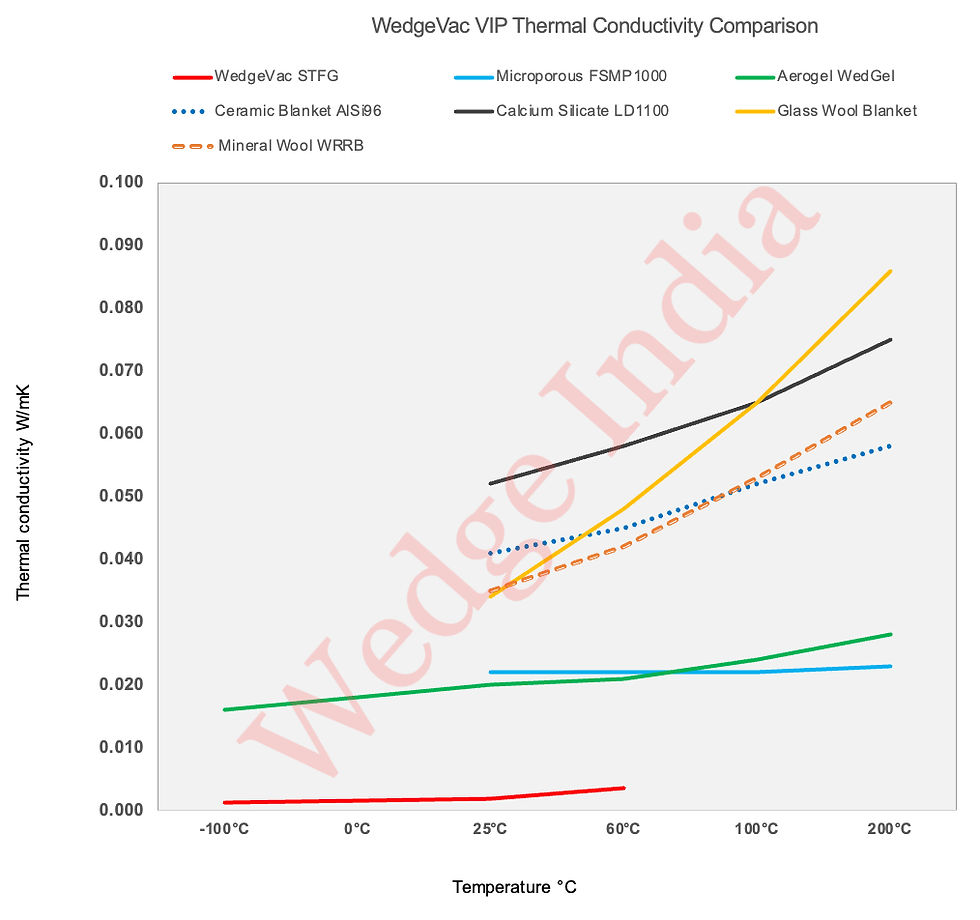

Vacuum Insulated Panels (VIPs) – Extremely low thermal conductivity, ultra-thin profile.

XPS (Extruded Polystyrene) – Good thermal insulation and compressive strength.

EPS (Expanded Polystyrene) – Low-cost insulation for walls, floors, and packaging inserts.

2. Flexible Blanket/Mat Insulations

Best for pipework, tank jackets, small portable containers, and retrofit upgrades.

Aerogel Insulation Blankets – Very low thermal conductivity, thin, lightweight.

Mineral Wool / Rockwool – Fire-resistant, durable for high-temperature cold storage equipment.

Fiberglass Insulation – Affordable, but needs proper sealing against moisture.

3. Spray-Applied Insulations

Used for retrofitting and sealing gaps in transport vehicles, cold storage walls, and roofs.

PU Spray Foam – High R-value per inch, air-tight sealing.

Polyurea Coatings with Insulation Layers – Combines waterproofing and insulation.

4. Specialty Packaging Insulations

For last-mile delivery, pharma logistics, and high-value shipments.

EPS & XPS Box Liners – For insulated shippers.

VIP-Based Thermal Shippers – For extreme performance (pharma-grade).

Gel Packs / PCM (Phase Change Material) Packs – Maintain specific temperatures inside insulated boxes.

Reflective Foil Insulation (Radiant Barriers) – Reduces radiant heat transfer in transport packaging.

Multi-Layer Thermal Blankets – For covering pallets or containers.

5. Hybrid Insulation Systems

Combining materials for optimal performance and cost-effectiveness.

PIR + VIP Hybrid Panels – For maximum insulation in thin walls.

Aerogel + PU Foam Jackets – For ultra-thin high-performance pipe and equipment insulation.

XPS + Reflective Foil Liners – For transport boxes with extra radiant protection.

Cold Chain Insulation Material Selection Chart – Wedge India

Material Type | Best Temperature Range | Typical Applications | Key Advantages | Limitations |

PIR (Polyisocyanurate) Panels | -40°C to +20°C | Cold rooms, walk-in freezers, reefer containers | High R-value, fire-resistant, moisture-resistant | Higher cost than PUF |

PUF (Polyurethane Foam) Panels | -40°C to +15°C | Cold rooms, reefer trucks, portable storage units | Good thermal performance, cost-effective | Lower fire resistance |

Vacuum Insulated Panels (VIPs) | -80°C to +25°C | Pharmaceutical shippers, ultra-cold storage, high-value goods | Extremely low thermal conductivity, ultra-thin | Expensive, sensitive to punctures |

XPS (Extruded Polystyrene) | -30°C to +20°C | Floor insulation, packaging inserts, insulated boxes | High compressive strength, moisture resistance | Lower fire resistance, medium R-value |

EPS (Expanded Polystyrene) | -25°C to +15°C | Transport box liners, low-cost cold storage, packaging | Affordable, lightweight | Lower insulation value compared to XPS |

Aerogel Insulation Blankets | -50°C to +200°C | Pipe/tank jackets, space-limited containers, hybrid systems | Very low thermal conductivity, thin, flexible | High cost |

Mineral Wool / Rockwool | -20°C to +650°C | Equipment insulation, fire-rated cold storage areas | Fireproof, soundproof | Needs vapor barrier for moisture protection |

Fiberglass Insulation | -20°C to +250°C | HVAC ducts, cold storage piping | Affordable, easy to install | Moisture-sensitive, requires sealing |

PU Spray Foam | -40°C to +25°C | Retrofitting cold storage, sealing gaps | High R-value per inch, airtight | Requires skilled application |

Reflective Foil Insulation | 0°C to +30°C | Transport packaging, last-mile delivery liners | Reflects radiant heat, lightweight | Not effective alone for extreme cold |

Phase Change Materials (PCM) | +2°C to +8°C / -18°C | Pharmaceutical transport, last-mile delivery | Maintains specific temp ranges, reusable | Limited duration without backup insulation |

Multi-Layer Thermal Blankets | -30°C to +30°C | Pallet covers, container wraps | Flexible, reusable, good short-term protection | Less effective for long-term storage |

Top Insulation Materials for Cold Chain Logistics in Gurugram

1. PIR (Polyisocyanurate) Panels

Best for: Cold storage rooms, reefer containers, walk-in freezers.

Benefits: High thermal resistance, moisture resistance, and fire performance.

2. Aerogel Insulation Blankets

Best for: Ultra-thin insulation where space is limited.

Benefits: Extremely low thermal conductivity, lightweight, and flexible.

3. VIPs (Vacuum Insulated Panels)

Best for: Pharmaceutical cold boxes and high-value goods.

Benefits: Exceptional thermal performance with minimal thickness.

4. XPS (Extruded Polystyrene) & EPS (Expanded Polystyrene)

Best for: Packaging inserts, insulated pallets, box liners.

Benefits: Cost-effective and durable for temperature-controlled shipments.

Where to Buy in Gurugram – Wedge India

At Wedge India, we supply world-class insulation solutions tailored for the cold chain industry in Gurugram and across India.

Our cold chain insulation range includes:

PIR insulated panels

Aerogel sheet jackets

VIP boxes

XPS/EPS thermal liners

Hybrid insulation kits for specific temperature ranges (2–8°C, -18°C)

📞 Request a Quote Now – Get expert advice and the right product for your application.

Cold Chain Applications We Serve

Food processing and distribution

Dairy and beverage supply

Pharmaceutical storage & transport

E-commerce and grocery delivery cold boxes

Hospital and medical cold rooms

FAQs

Q1: What is the most efficient insulation for cold storage in Gurugram?A: PIR panels and VIPs are among the most efficient due to their low thermal conductivity and long lifespan.

Q2: Can insulation materials be customized?

A: Yes. At Wedge India, we provide custom-cut panels, jackets, and liners based on your exact dimensions.

Q3: How do I choose between PIR, Aerogel, and VIP?

A: PIR is cost-effective for large cold rooms, Aerogel is ideal for space-constrained areas, and VIPs are best for maximum performance in portable solutions.

Q4: Do you provide installation services in Gurugram?

A: Yes, our team offers full installation support for panels, jackets, and modular cold rooms.

Conclusion

For cold chain operators in Gurugram, investing in the right insulation material is a smart business decision. It improves temperature control, cuts energy costs, and safeguards your products from spoilage.

With Wedge India’s premium insulation solutions, you get reliability, efficiency, and performance — all backed by industry expertise.

🚀 Get in touch today and build a more efficient cold chain operation! Enquire Online