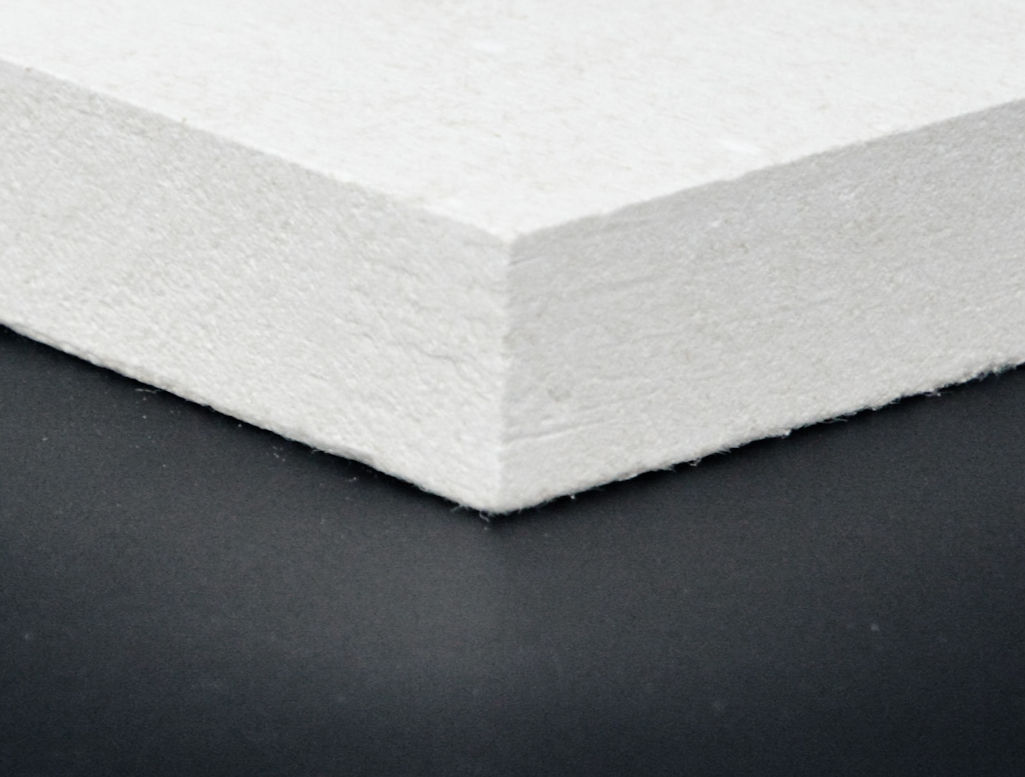

Buy Calcium silicate boards with a density of 260 kg/m³ and dimensions of 600 x 150 x 100 mm 600 to 1100°C, low price INR 229 / Pc at Wedge India.

These boards are particularly suitable for thermal insulation in high-temperature industrial applications, such as in cement plants. These boards offer excellent thermal insulation properties, durability, and resistance to high temperatures, making them a reliable choice for such demanding environments.

Properties of Calcium Silicate Board (Density 260 kg/m³, Size 600 x 150 x 100 mm)

Thermal Insulation

Low Thermal Conductivity: With a low thermal conductivity, typically between 0.05 to 0.1 W/m·K, these boards provide excellent thermal insulation.

Consistent Performance: Maintains effective insulation properties across a broad temperature range, ensuring consistent performance.

High-Temperature Resistance

Service Temperature: Can withstand temperatures up to 1100°C or higher, making them suitable for high-temperature equipment and environments.

Thermal Stability: Stable and resistant to thermal shock, preventing shrinking, warping, or cracking under high temperatures.

Durability and Mechanical Strength

High Compressive Strength: Provides good mechanical strength, ensuring durability and resistance to mechanical stress and impact.

Density: At 260 kg/m³, the board offers a balance of lightweight properties and mechanical robustness.

Applications in Industrial Settings

1. Cement Plants

- Rotary Kilns: Insulating the interior surfaces to reduce heat loss and protect the kiln shell from high temperatures.

- Coolers and Preheaters: Acting as thermal barriers to maintain optimal process temperatures and improve energy efficiency.

- Boilers and Ducts: Insulating to reduce heat loss and enhance system efficiency.

- Clinker Silos and Storage Bins: Maintaining stable temperatures to prevent condensation and thermal damage.

- Furnaces and Combustion Chambers: Providing high-temperature insulation to protect these structures from extreme heat.

2. Power Plants

- Steam Pipes and Boilers: Insulating to enhance energy efficiency and safety by maintaining high temperatures.

- Turbine Insulation: Protecting turbines from thermal damage and maintaining operational efficiency.

3. Petrochemical Plants

- Process Vessels: Insulating reactors and other process vessels to manage heat effectively.

- Pipelines: Ensuring minimal heat loss in high-temperature fluid transport.

4. Steel Plants

- Ladle and Tundish Insulation: Providing thermal insulation to prevent heat loss in molten metal handling equipment.

- Furnace Linings: Enhancing energy efficiency and protecting structural components from high temperatures.

5. Ceramic and Glass Manufacturing

- Kilns: Insulating kiln walls and roofs to maintain high operating temperatures and reduce energy consumption.

- Annealing Ovens: Ensuring consistent temperatures for quality control in the production process.

Calcium silicate boards with a density of 260 kg/m³ and dimensions of 600 x 150 x 100 mm are highly effective for thermal insulation in a wide range of industrial applications. Their excellent thermal insulation properties, high-temperature resistance, durability, and fire safety make them ideal for use in cement plants, power plants, petrochemical plants, steel plants, and ceramic and glass manufacturing.